Argus E35 Tooling DevelopmentThe first stage of construction requires the building of temporary plugs that are identical in shape to the finished production boat. A female mold is taken that is then used for the production of the actual vessel parts. The following sequence shows the progression from frames to finished moulds. |

Frames CNC machined ready for assembly

Frames assembled on a strongback

Frames are planked with MDF

Main hull ready for fairing

Assembling hull plug

Faired and ready for mould (click to enlarge)

Constructing Mould

Finished Mould

Start of deck plug

CNC framing detail

Deck planking finished

Aft View

Foredeck

Cabin

Aft Deck

Trial fitting nonskid patterns

Saloon roof framing

Saloon roof faired

Saloon roof plug painted

Deck Plug Painted

Aft Deck Plug Painted

Non Skid Pattern Checking

Non Skid Pattern Down and Tooling Gelcoat on Roof

Non Skid Detail

Front Deck Non Skid

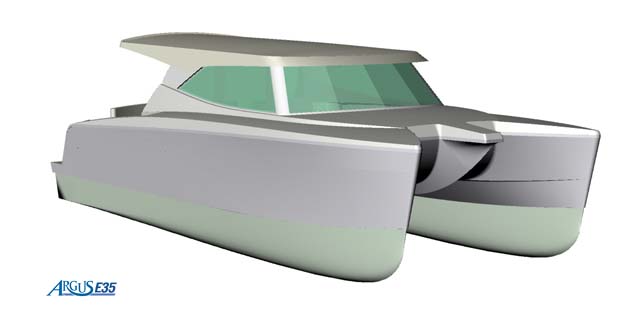

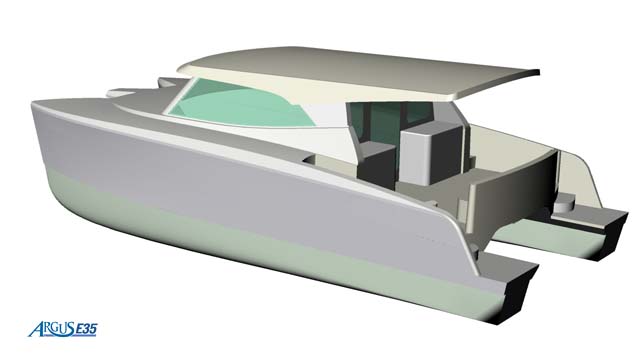

360 degree animation

New bow design showing wave breaker nacelle

Stern view highlighting bridgedeck clearance

Extended brow offering increased shade area

Sister Ship PhotosThe Argus E35 is an evolution of an earlier displacement catamaran design by Roger Hill. Following is a selection of photographs that highlight the basic design features. |

Shiraz at speed displays only a small water disturbance

The waterline is the same at speed or stationary

Outpost at anchor demonstrates the shallow draft

Shiraz bow wave under heavier conditions

Galley down configuration on Shiraz

Shiraz again showing off the minimum wake

Honda BF90 installation on Shiraz

Intrepid ready for charter service by Sea Star Cruises

Master cabin on Intrepid - port cabin is mirror image

Master cabin on Intrepid - port cabin is mirror image

Starboard head on Intrepid - port head is mirror image

Starboard head on Intrepid - port head is mirror image